Review article

Review article

Leaching Technologies – The Path of Revival Potential of Mining Enterprises

Golik Vladimir Ivanovich*

Doctor of Engineering, Sciences, Professor, Professor of the Moscow Polytechnic University, Moscow

Golik Vladimir Ivanovich, Doctor of Engineering, Sciences, Professor, Professor of the Moscow Polytechnic University, Moscow.

Received Date:March 11, 2024; Published Date:March 18, 2024

Abstract

With the change in the economic structure, many mining enterprises of the mining countries of the world cease to function, one of the reasons for which is the weakening of the mineral resource base for the production of metals. The state strategy for the development of states in increasing the contribution of the extractive industry to the economy, therefore, the search for reserves to increase production, first of all, strategic and valuable, is a very urgent scientific and production task. Restoration of the potential for the production of non-ferrous metals is possible with the involvement in the exploitation of substandard raw materials for traditional mining and processing technologies. Back in the middle of the last century, priority was given to development systems with open or unsystematically filled with mining products, which reduced the quality of ores and increased the cost of metals. The development of depleted reserves of metal deposits is possible by new leaching technologies based on the conversion of metals into easily soluble compounds and the subsequent extraction of metals from the collective solution. This technology was implemented in the extraction of polymetals at the mines of the USSR and Russia. Increasing the production capacity of enterprises by attracting substandard raw materials for traditional technology can ensure profit, especially when combining a new technology with a traditional one. It is important that it becomes possible to extract all the target components contained in the tailings, which increases the recoverable value of the raw material. The peculiarities of the localization of ore deposits are favorable for the allocation of areas of concentration of lost ores within the spent ore bodies, and their leaching with the supply of reagent solutions and the release of metal-saturated solutions through wells from the surface.

Keywords:Metal; Ore; Deposit; Condition; Technology; Leaching; Extraction; Reagent; Activation

Introduction

As a result of the reform of 1990, with a change in pricing policy and a reduction in financing for geological exploration, the mineral resource base weakened and a shortage of profitable metals for mining at mining enterprises previously subsidized by the state was revealed [1,2]. One of the directions of survival of such enterprises is the strengthening of the raw material base by involving off-balance ores, sorted poor ores and tailings of raw material beneficiation in production [3,4,14].

The share of the mining and processing industry in the structure of the gross regional product of Russia is about 10%, so innovative improvements in the extraction and processing of mineral raw materials provide important economic advantages.

Modern ore beneficiation technologies are not always effective in the processing of metal-poor mineral raw materials.

In the recent past, open-pit mining systems have been used in the development of deposits, which have contributed to ore losses of up to 20% and dilution of up to 60%. Thus, the amount of ores lost in the Sadon deposits (Republic of North Ossetia) together with disseminated rocks reaches 30 million tons. At the deposits of the Sadonsky ore cluster, passive reserves are confined to the flanks and deep horizons of the deposits.

The Tyrnyauz fields were developed by floor-chamber and sublevel caving development systems. At the fields of the Urup group, development systems with the backfilling of the mined-out space are used only when extracting reserves under the Urup River.

In the case of open-pit mined deposits, ore recovery does not exceed 85%, and ore dilution with rock does not exceed 30%. Substantiation of ways to modernize the development of such deposits on the basis of substandard raw materials is the goal of many studies in this area, but the relevance of this problem only increases over time.

Outcomes

The main reason for the low quality and high cost of production is that the reserves are depleted with the advanced extraction of rich ores [5-7,16].

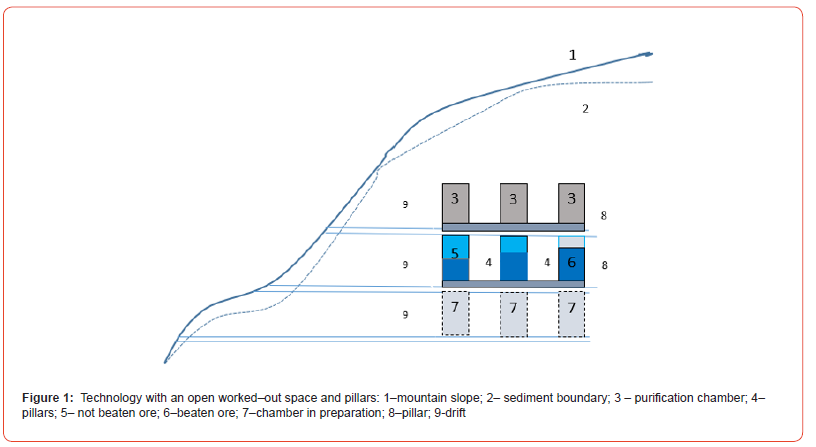

Natural and man-made factors reduce the possibilities for the effective use of traditional technologies and stimulate the search for new technologies for the profitable development of the remaining reserves. At most deposits, especially valuable and rareearth ores, the mined space was either left open or haphazardly filled with waste from workings, which moved downwards during undermining and reduced the quality of subsoil use. High quality indicators during the development of the primary treatment chambers decreased when the pillars were extinguished (Figure 1).

Cost-effective operation of deposits of this type is possible with the use of innovative technologies based on the phenomenon of chemical oxidation and conversion of metals into easily soluble compounds with subsequent extraction from solution.

In the last century, zinc and lead were precipitated from mine effluents with chemical reagents at the deposits of the Sadonsky ore cluster, and an underground leaching mine functioned, and cathode zinc, zinc oxide, zinc sulphate and other products were obtained from the concentrate. An important advantage of the new technology is the possibility of almost complete recovery of metals that are currently migrating into the environment [8-10,15,18].

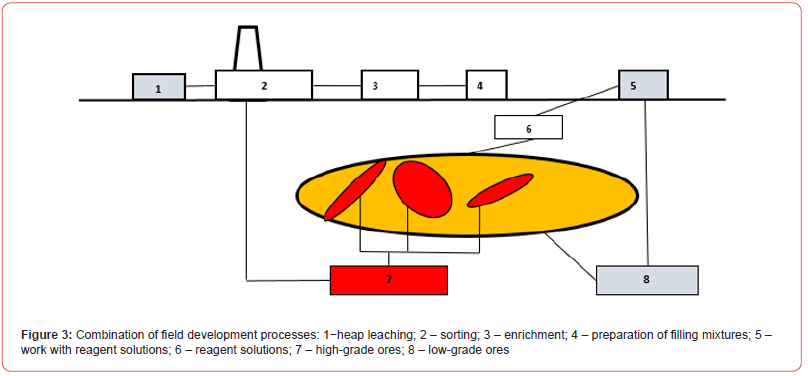

Increasing the production capacity of enterprises by attracting additional resources can make the enterprise profitable if the smaller, but more metal-containing ores are processed by traditional methods, and a larger part is leached at the site. In this case, the end-to-end recovery factor can even exceed the value of conventional processing.

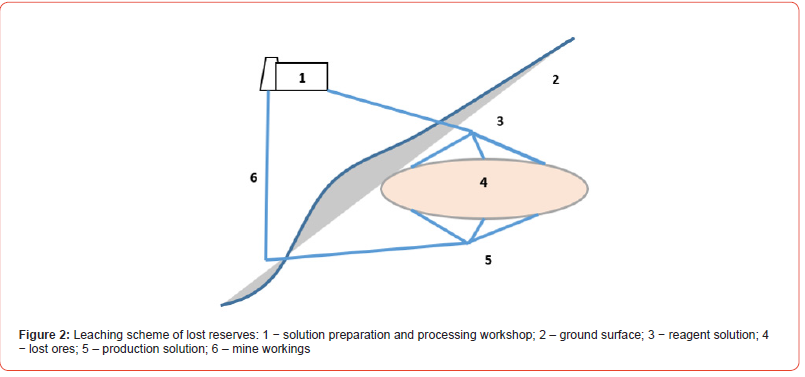

The project implemented the idea of supplying a reagent solution from the surface through wells and dispensing metal-saturated solutions for processing concentrates at a hydrometallurgical plant.

The prime cost of 1 ton of metals was 352 rubles at the prices of that time, while the cost of metals extracted by traditional technology was 900 rubles per ton.

The new technology comprehensively solves all the problems of mining production: recovery of up to 70% of lost metals, profit from the sale of waste products and reduction of environmental damage from the storage of tailings.

The capabilities of the leaching technology are confirmed by the experience of 30 years of development of one of the North Caucasian fields, which was leached for 30 years after the exhaustion of conditioned reserves [11].

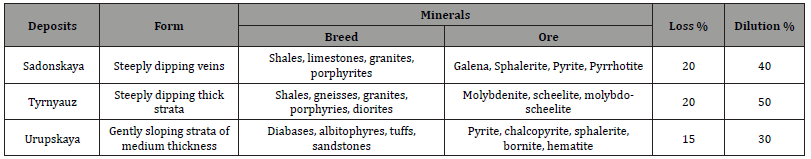

Mining enterprises of the Northern slope of the Caucasus are united by the fact that the mined ores are of low quality, which increases labor and energy costs during processing (Table 1).

Table 1:Indicators of the quality of mined ores.

In the Urals, copper is leached from lost ores. This scheme can be analogous to the leaching of metals from lost technologically exposed ores. The information accumulated during the extraction period on the geography of the lost ores makes it possible to identify promising areas for leaching within the mined-out area and apply the development system of leaching by wells from the earth’s surface (Figure 2).

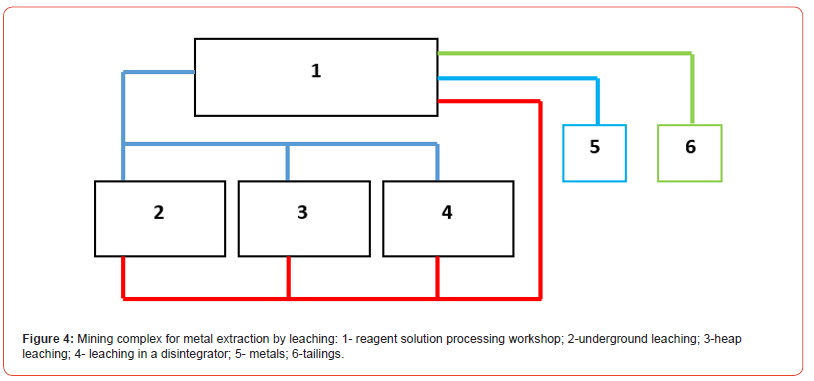

Increasing the activity of metal-containing minerals is achieved by treatment with surfactants in the created force field, when reagents are supplied to microcracks under high pressure under combined mechanical and chemical action (Figure 4) [12,13,19].

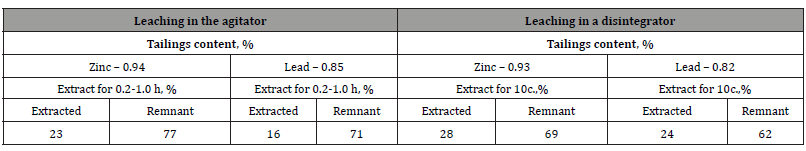

The results of activation leaching of metals from ore tailings are almost identical to the results of leaching in the disintegrator, but the same result is achieved within 2 orders of magnitude more time (Table 2).

Table 2:Extraction of metals into solution.

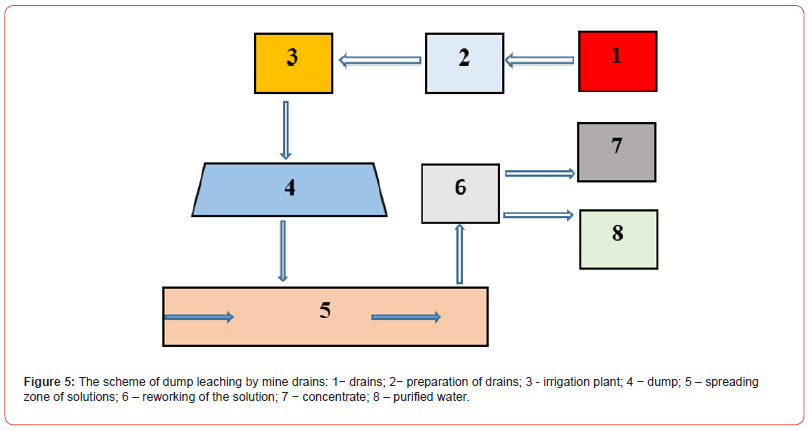

The risk of natural leaching of lost stocks is reduced by the creation of a mine effluent management system, in which the reduction of the risk of chemical contamination is combined with the production of metals during the disposal of mine and dump effluents (Figure 5).

Metal leaching technologies may be in demand when it is necessary to average the content of concentrates of different grades of ores under production conditions.

Conclusion

Involvement in the production of substandard raw materials for traditional technology is a way to restore the potential of degraded mining enterprises. The implementation of this direction is carried out within the framework of the concept of combining production technologies, which includes leaching components in blocks, heaps and high-speed mills - disintegrators. The mechanochemical activation of the leaching processes in the disintegrator significantly reduces the time required to extract the same amount of metals into solution.

Acknowledgement

None.

Conflict of Interest

None.

References

- Dmitrak Yu V, Kamnev EN (2016) "Leading Design, Survey and Research Institute of Industrial Technology". Mining magazine 3: 6-12

- Sorokozherdyev VV, Khasheva ZM, Konstantinidi Kh A (2013) Izmereniya strategii modernizatsii Rossii [Measurements of the strategy of modernization of Russia] T 11(4): 143-146.

- Golik V I, Klyuev R V, Martyushev N V, Zyukin D A, Karlina A I, et al. (2023) Technology for nonwaste recovery of tailings of the mizur mining and processing plant. Metallurgist 66(11-12): 1476-1480.

- Ben-Awuah E, Richter O, Elkington T, Pourrahimian Y (2016) Strategic mining options optimization: Open pit mining, underground mining or both. International Journal of Mining Science and Technology 26(6): 1065-1071.

- Lyashenko VI (2015) Environmental Technologies for the Development of Complex Structural Deposits of Minerals. Mine Surveying Bulletin 1: 10-15.

- Morkun V, Savytskyi O, Ruban S (2015) The use of heat pumps technology in automated distributed system for utilization of low-temperature energy of mine water and ventilation air. Metallurgical and Mining Industry 6: 118-121.

- Golik VI, Klyuev RV, Martyushev NV, Kondratiev VV, Tynchenko VS, et al. (2023) Reuse and Mechanochemical Processing of Ore Dressing Tailings Used for Extracting Pb and Zn. Materials 16(21): 7004.

- Ilyin S A, Kovalenko V S, Pastikhin DV (2012) Open method of developing deposits: opportunities and ways of improvement. Mining Journal 2: 87-92.

- Klyuev RV, Bosikov II, Mayer AV, Gavrina OA (2020) Comprehensive analysis of the application of effective technologies for improving the sustainable development of the natural and technical system. Sustainable development of mountain territories 2: 283-290.

- Chanturia V A (2017) Scientific Justification and Development of Innovative Processes of Complex Processing of Mineral Raw Materials. Mining Journal 11: 67-84.

- Klyuev RV, Bosikov II, Egorova EV, Gavrina OA (2020) Assessment of mining and geological and mining conditions of the Severny quarry with the help of mathematical models. Sustainable development of mountain territories 3: 418-427.

- Sinclair L, Thompson J (2015) In situ leaching of copper: Challenges and future prospects. Hydrometallurgy 157: 306-324.

- Golik VI, Khasheva ZM, Galachieva SV (2015) Diversification of the economic foundations of depressive mining region. The Social Sciences 10(6): 746-749.

- Ilyin S A, Kovalenko V S, Pastikhin D V (2012) Overcoming the initial shortcomings of the open method of development: experience and results 4: 98-103.

- Kaplunov D R, Radchenko D N (2017) Principles of design and choice of technologies for the development of mineral resources, ensuring the sustainable development of underground mines 11: 67-74.

- Bunin I Zh, Ryazantseva MV, Samusev AL, Khabarova IA (2017) Theory and Practice of Application of Combined Physicochemical and Energy Effects on Geomaterials and Aqueous Suspensions 11: 134-139.

- King B, Goycoolea M, Newman A (2017) Optimizing the open pit-to-underground mining transition. European Journal of Operational Research 257(1): 297–309.

- Stefanescu D, Foidas I (2017) Recovery factor and replacement ratio of reserves, key parameters of monitoring the natural gas process. Proceedings of the 17th International Multidisciplinary Scientific GeoConference SGEM 2017. STES92 Technology Ltd 17(14): 843– 850.

- Jang H, Topal E, Kawamura Y (2015) Decision support system of unplanned dilution and ore-loss in underground stoping operations using a neuro-fuzzy system. Applied Soft Computing Journal 32: 1-12.

- Babkin V V, Uspenskiy D D (2015) New strategy. Chemistry-2030. High processing of raw materials. Clustering. Chemicalization of the industry of the Russian Federation pp. 222.

-

Golik Vladimir Ivanovich*. Leaching Technologies – The Path of Revival Potential of Mining Enterprises. Mod Concept Material Sci. 5(5): 2024. MCMS. MS.ID.000625.

-

Metal, Ore, Deposit, Condition, Technology, Leaching, Extraction, Reagent, Activation

-

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.